Heat Treating Services

Erie Steel Treating offers a wide variety of heat treating processes designed to accommodate both the large-volume production run manufacturer and the occasional heat treat user. Our services include:

Atmosphere Heat Treating Processes

• Annealing

Full Anneal, Process Anneal, Sub-Critical Anneal, Spheroidize Anneal

Envelope size 36″ X 72″ x 40″ {4000#}

• Normalizing

Envelope size 36″ X 72″ x 40″ {4000#}

• Stress Relieving

Envelope size 36″ X 72″ x 40″ {4000#}

• Neutral Hardening

Standard & Modified Mar-Quench capability

Envelope size 36″ X 72″ x 40″ {4000#}

• Carbonitriding

Standard & Modified Mar-Quench capability

Envelope size 36″ X 72″ x 40″ {4000#}

• Carburizing

Standard & Modified Mar-Quench capability

Envelope size 36″ X 72″ x 40″ {4000#}

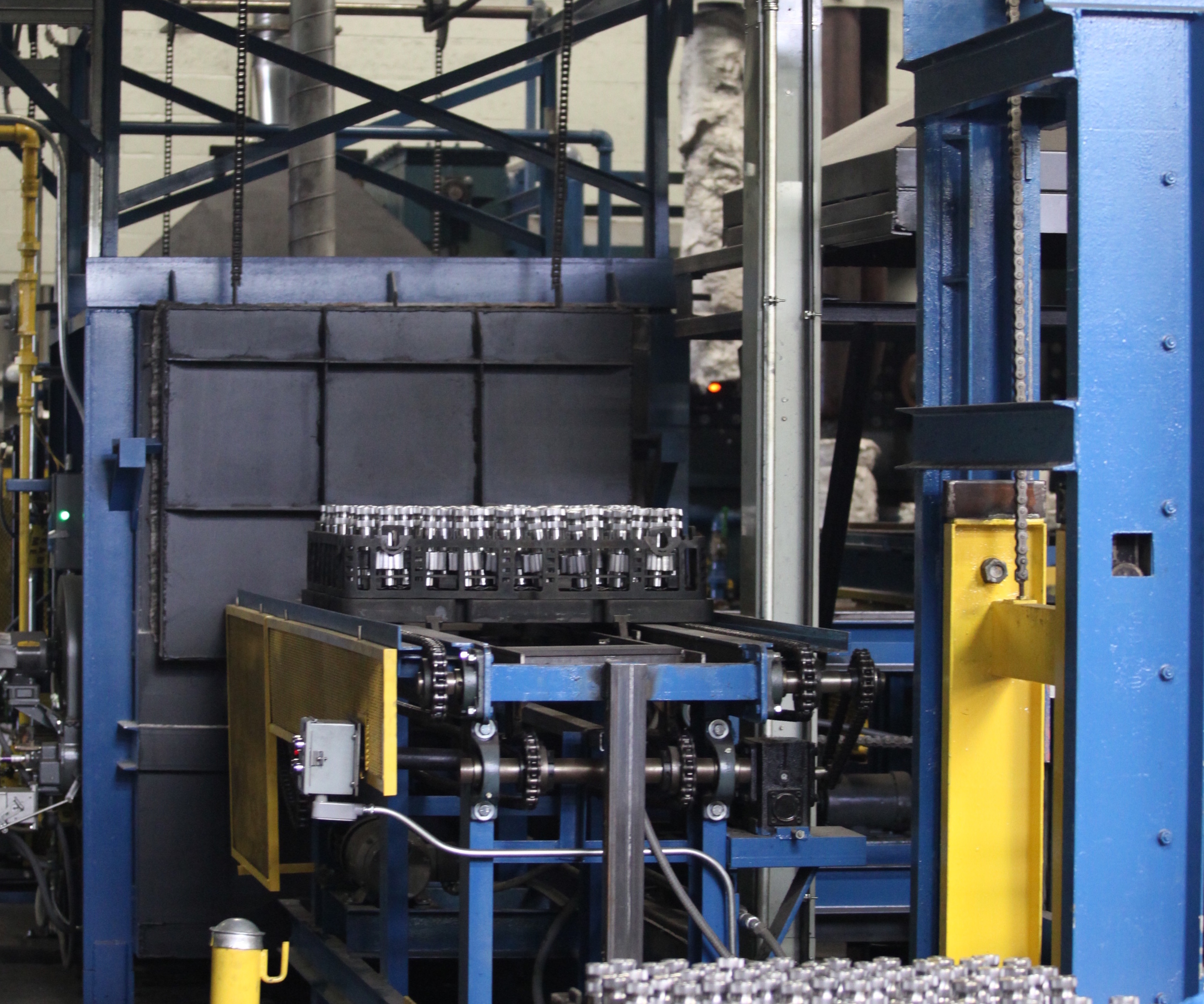

Atmosphere Heat Treating Equipment

• Batch Furnaces (4)

36x72x40 (4500 lbs)

• Pusher Furnaces (2)

36x32x22 (1200 lbs)

• Mesh Belt

1500 lbs per hour

Specialities

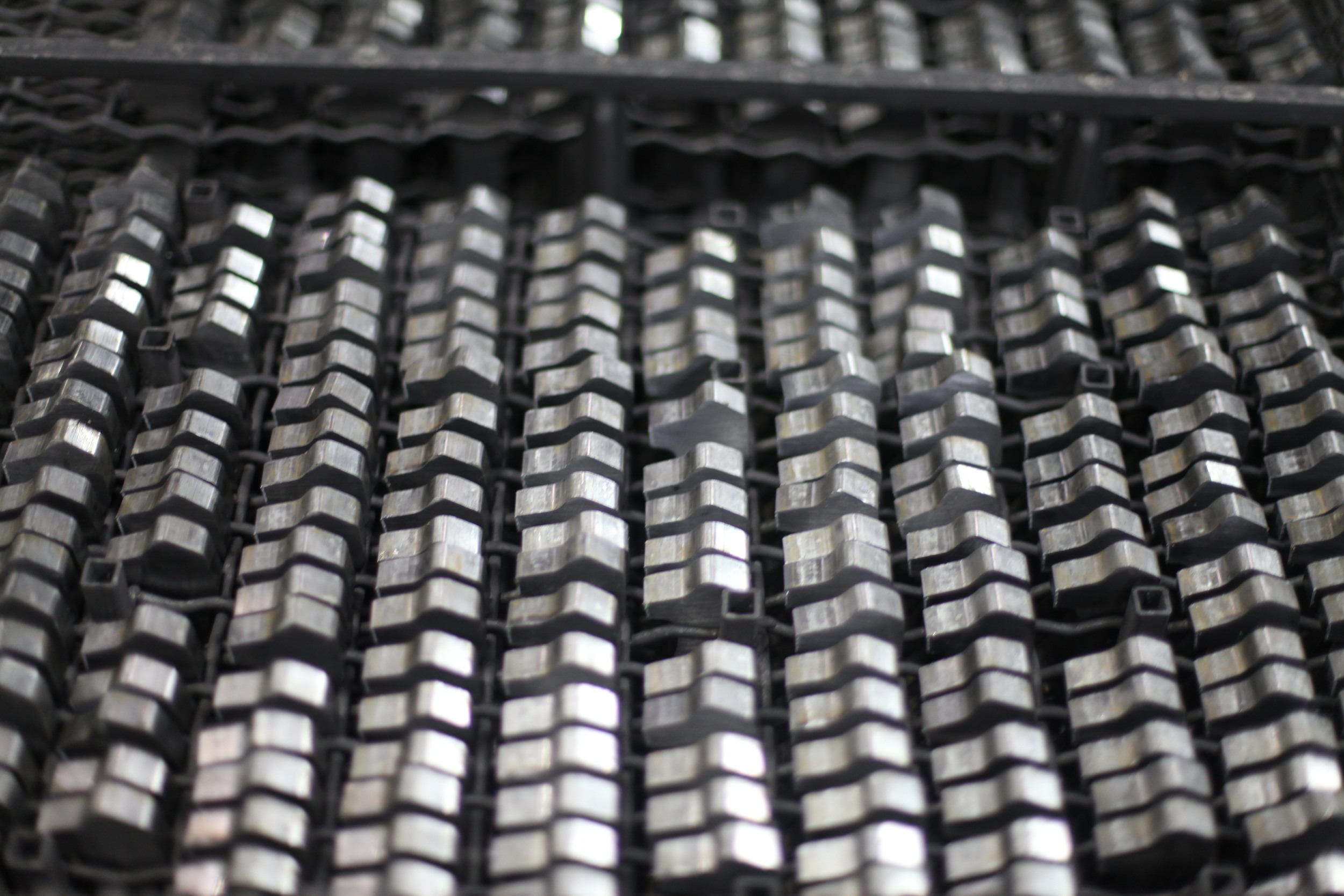

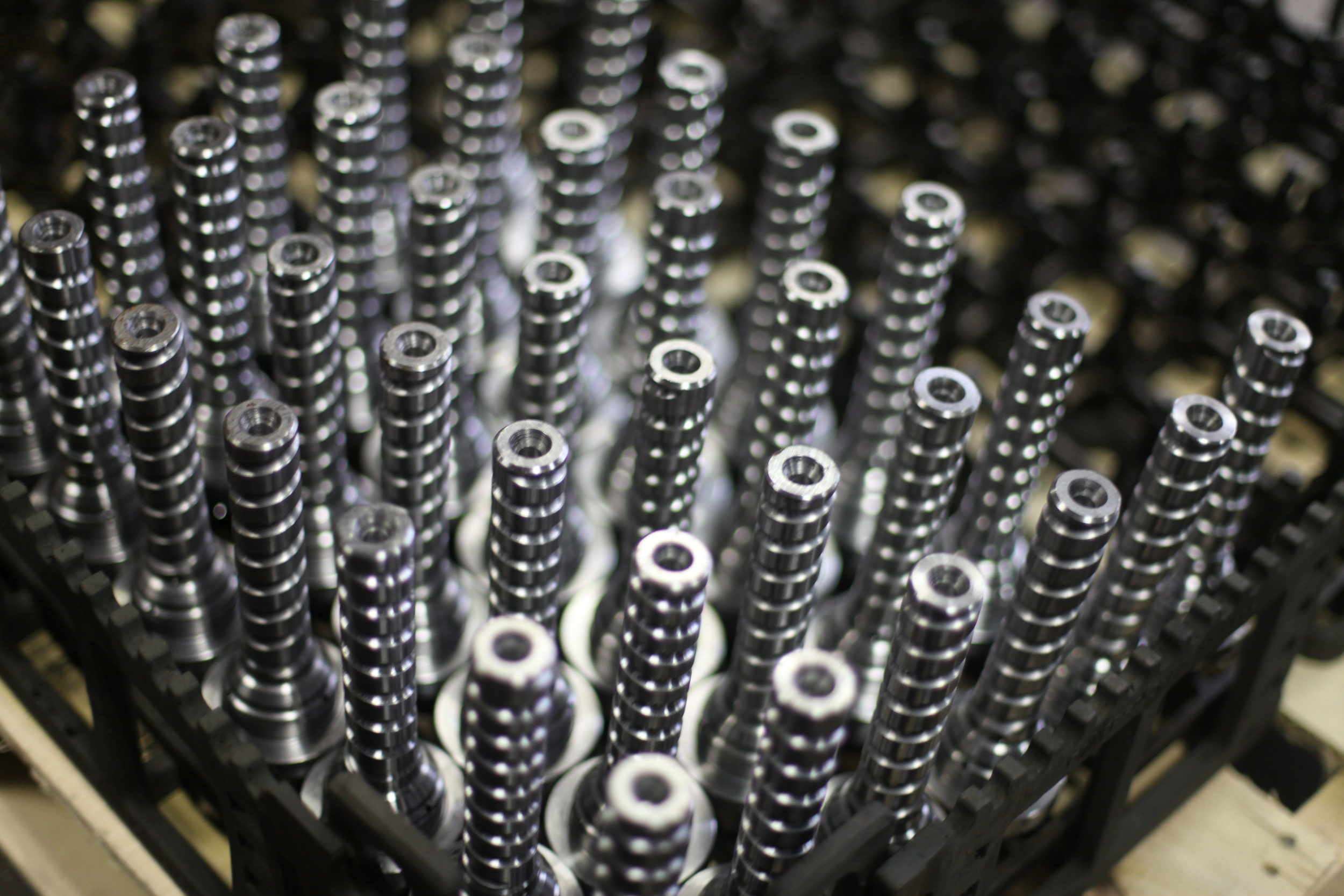

Distortion Critical work requiring part specific racking or fixturing

Metallurgically Critical work requiring part specific process engineering

Carburized Components including Gearing & Shafting

Serial Production requiring redundancy in processing centers to assure schedule adherence

Critical work requiring process documentation (i.e. data logging + photographic documentation of loading parameters)

Vacuum Heat Treating Processes

• Annealing

Full Anneal, Process Anneal, Sub-Critical Anneal, Solution Anneal

Sizes up to 48″ length

• Normalizing

Sizes up to 48″ length

• Stress Relieving

Sizes up to 48″ length

• Hardening

5 Bar & 10 Bar Quench

Sizes up to 48″ length

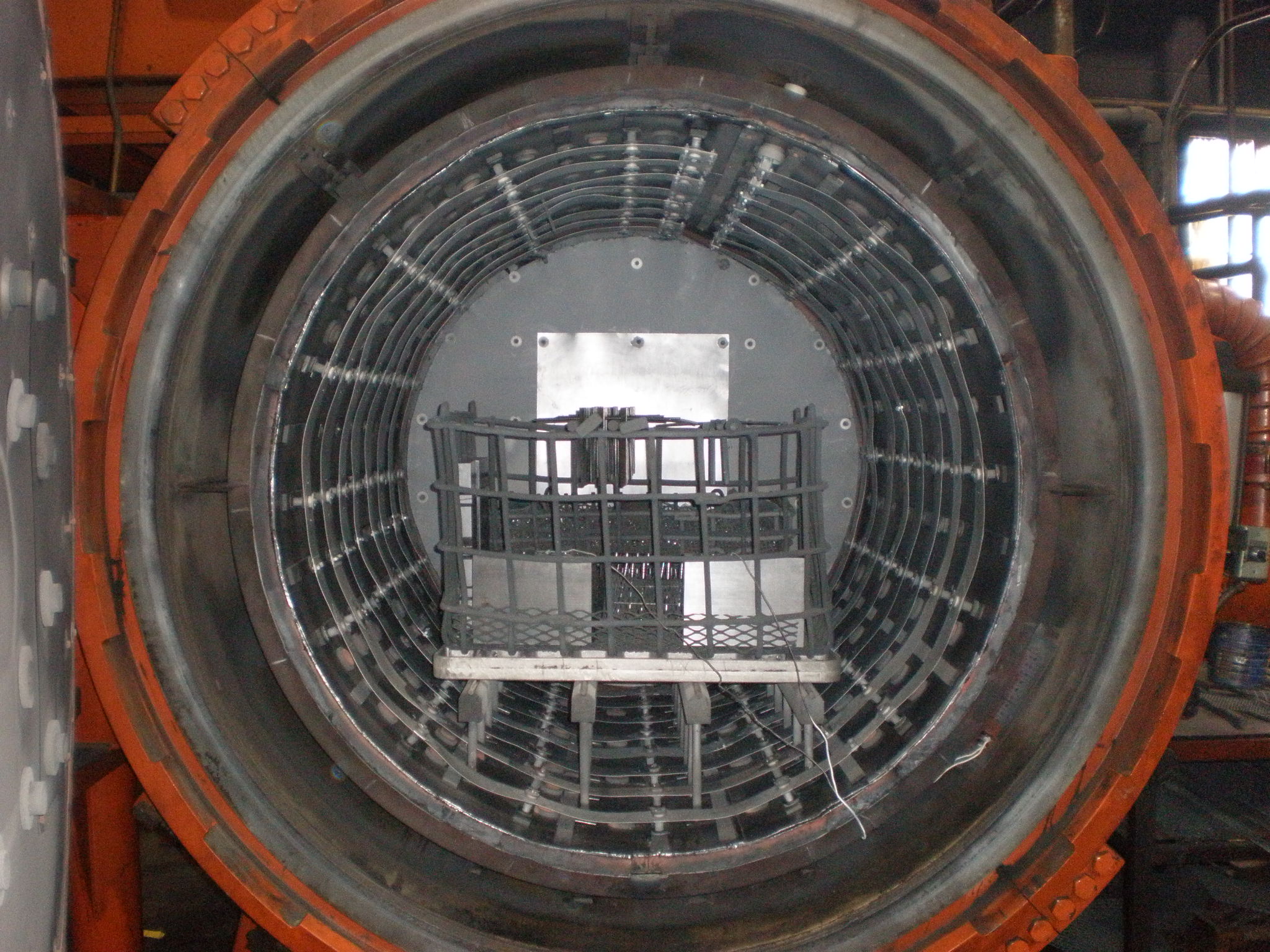

Vacuum Heat Treating Equipment

• 5 Bar Vacuum

24x36x24

• 10 Bar Vacuum

36x48x40

Specialities

• Tool & Die Processing

A-series, D-series, H-series & S-series materials vacuum processed gas quenched

• Stainless Steels

300– series, 400– series, precipitation hardening grades (17-4, 13-5 etc)

Other Capabilities

• Aluminum

Annealing (T-0) – Solution Annealing (T-4) – Precipitation Hardening (T-6) Stress Relieving

• Non-Atmosphere Annealing & Normalizing

• Shot Blast Cleaning

Rubber Belt Tumble Blast (2): 800 lb capacity. Rust Preventative Available.

Belt Blast: 24″ Width

• Welded Fabrication Stress Relieve

UP TO 8′-9′-15′